ARP 8740 CHROME MOLY:

Until the development of today’s

modern alloys, chrome

moly was popularly considered

a high strength material.

Now viewed as only moderate

strength, 8740 chrome

moly is seen as a good tough

steel, with adequate fatigue

properties for most racing

applications, but only if the

threads are rolled after heattreatment,

as is the standard

ARP production practice.

Typically, chrome moly is

classified as a quench and

temper steel, that can be

heat-treated to deliver tensile

strengths between 180,000

and 210,000 PSI.

ARP2000®:

An exclusive, hybrid-alloy

developed to deliver superior

strength and better fatigue

properties. While 8740 and

ARP2000 share similar

characteristics – ARP2000 is

capable of achieving clamp

loads in the 215,000-220,000

PSI range. ARP2000 is used

widely in short track and

drag racing as an up-grade

from 8740 chrome moly in

both steel and aluminum

rods. Stress corrosion and

hydrogen embrittlement

are typically not a problem,

providing care is taken

during installation.

ARP L19:

This is a premium steel

that is processed to deliver

superior strength and fatigue

properties. L19 is a very high

strength material compared

to 8740 and ARP2000 and

is capable of delivering

clamp loads in the 230,000-

260,000 PSI range. It is

primarily used in short track

and drag racing applications

where inertia loads exceed

the clamping capability of

ARP2000. Like most high

strength, quench and temper

steels – L19 requires special

care during manufacturing

to avoid hydrogen embrittlement.

This material is easily

contaminated and subject

to stress corrosion. It must

be kept well-oiled and not

exposed to moisture. |

•

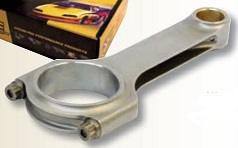

Forged from 4340 steel

•

Forged from 4340 steel